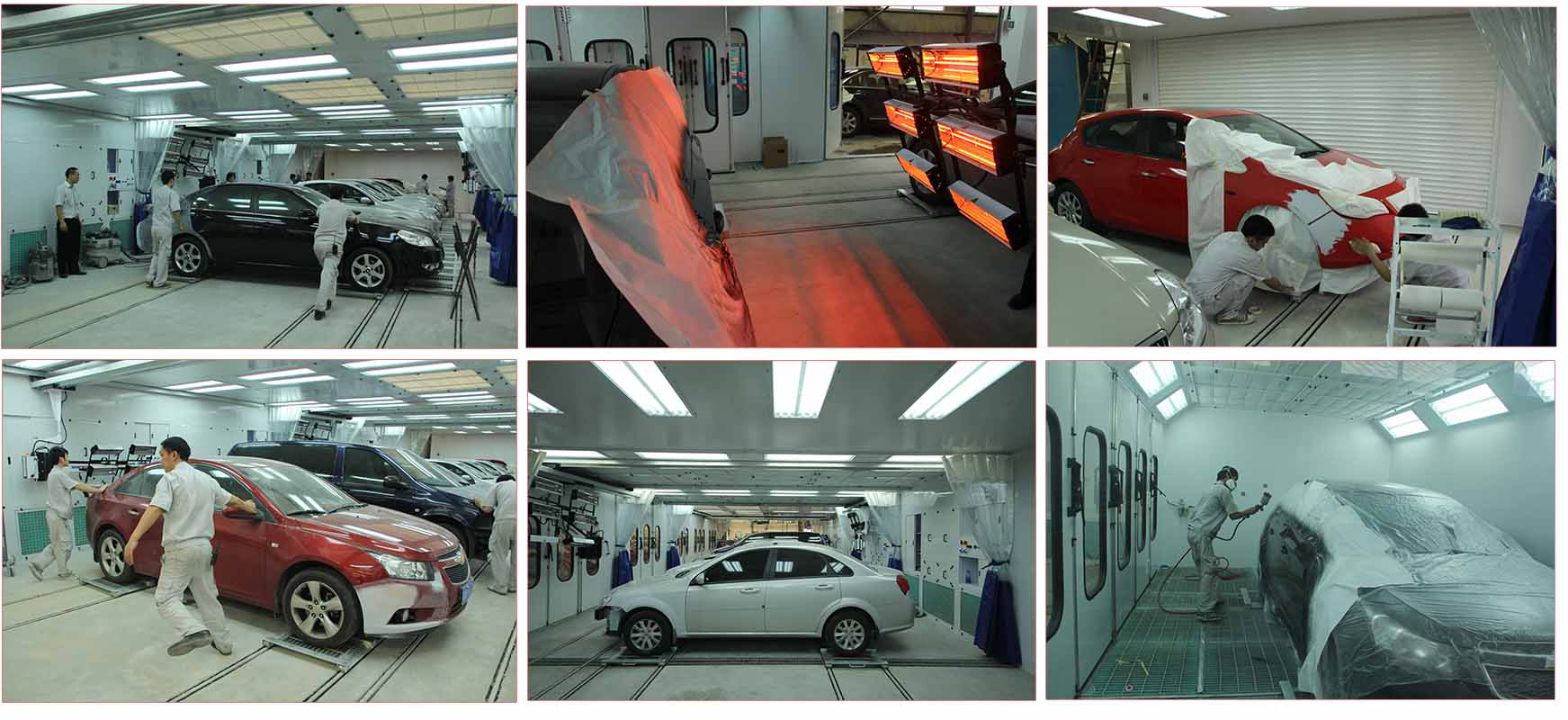

Spray Booth Production Line

What is the aim of building this Spray Booth Production Line?

We have designed the Spray Booth Production Line to meet the vehicle model’s specific requirements, production quantity, and repair shop site conditions.

This design aims to improve production efficiency and reduce costs for the 4S workshop. For instance, the Buick Spray Booth Production Line consists of eleven working stations: one Reserved Working Station, four paint preparation bays, one prep station for a floating coat, one prep station for shielding, two spray booths, and two polish rooms.

Who can use this production line effectively?

Different paint-finishing applications require different solutions. Manufacturers continuously improve material design and technology to ensure the quality supply of Prep Stations and Spray Booth Working Stations based on project needs.

Appointing experienced staff for high-end prep and spray booth working stations is essential. They should know the latest technology models and international quality standards.

Who is the best choice to design and produce it?

Manufacturers like YOKISTAR provide custom solutions to meet the demand for the most significant automobile paint-finishing applications so that the most efficient prep stations can be readily available.

Do You Have A New Project In Your Mind?

Can We Offer Any Help?